Bioenergy may be good for the climate, but it is not very efficient. The same applies to biotechnology, which uses plants as raw materials. “Since starch is obtained from crops such as potatoes, maize and cereals, this is causing competition between our plates and our fuel tanks. When you make plastics or fuels from starch, you inevitably rely on sources of food. In view of food insecurity, starch-based biotechnology has no sustainable future,” explains Wilhelm. For this reason, he and his colleagues have treated algae in such a way that they do not form any biomass, but excrete organic carbon into the nutrient solution as glycolic acid. This can be used in a variety of applications, including for producing liquid or gaseous fuels as well as plastics.

The process initiated by the biologists has achieved such high concentrations that the nutrient solution can be used directly as a glucose substitute. Neither purification nor complex nutrient recycling is necessary, as the nutrient salts can be circulated. The process is considerably more area-efficient, robust, does not require fertiliser and can be integrated into environmentally friendly landscape concepts.

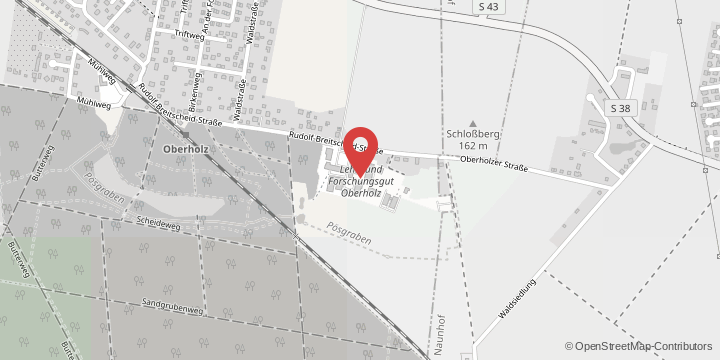

“If no biomass is produced, then you don’t need any fertiliser, such as nitrogen, phosphate or potassium. This saves energy and protects the environment. Without the formation of biomass, significantly more organic carbon is produced per hectare, as the cells do not have to expend energy to convert sugar into energy-rich molecules such as proteins and fats. This increases efficiency,” explains the biologist. For the first time, the researchers have shown that it is possible to produce glycolic acid with a continuously high degree of efficiency. “This is the decisive step towards technical implementation, for example constructing a demonstration plant and testing it in real operation,” explains Wilhelm. This in turn is the basis of a new technology that could be the central building block for a transformation concept at former opencast lignite mines, enabling an integrated ecological and biotechnological design at recultivation sites.

Original title of the publication in Plant Biotechnology Journal 2019:

“Glycolate from microalgae: an efficient carbon source for biotechnological applications” DOI: 10.111/pbi.13078)